Most of pulp&paper plants and crude refineries among others industrial facilities, and also an in-creasing number of waste water treatment plants, protect their electronics from environmental co-

rrosivity.

During the productive process, some acid and/or corrosive gases are released, such as hydrogen sul-phide, SO2, ozone, nitric oxides, etc. These gases come into the electrical rooms through the doorsand windows, HVAC systems or others, creating a highly corrosive environment inside and thus af-fecting electronic instrumentation.

To protect electronics from this environmental corrosivity we must keep them away from corrosivegases. How could we do this? First of all, we have to ensure thatall the indoor air has been chemi-cally filtrated with the proper system. Then we have toreach some possitive pressurization inside(20 Pa is the goal).

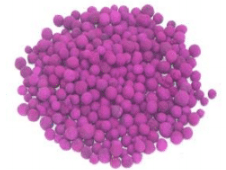

The most appreciated filtration media for this application is potassium per- manganate impregnated activated alumina spheres . Depending on the gas mixture, should be needed an air filtration s ystem filled with several stages in series of chemical filtration with some other di fferent medias able to remove more contaminants.

Alphachem, the air treatment bussines unit of Greenkeeper Iberia, has a broad range of filtration and presurization units ready to create a corrosive-free environment that will protect your electronic

instrumentation from pernicious effects of environmental corrosivity:

- Alphachem SFM units. Can supply up to 25,000 m3/h of corrosion-free air. It is used for pre-surization of control rooms and also for filtration of recirculated air or intake air, when con-centrations of corrosive gases are moderate.

- Alphachem PBS units. Strongly recommended when high corrosive gases concentrations arepresent. Quite usefull for electrical rooms pressurizationin some industries with severe environmental corrosivity,specially in petrochemical & refining.

- Alphachem SPV units. Performe a double task:

- Room presurization

- Filtration of indoor air.

This equipment is widely used in small control rooms, upto 150 m2.